Exhibit Design Search / Trade Show and Event Tips / Design, Lighting, and Graphics Tips /

Considering a Lightbox? 8 Factors to Consider

What to Look for in an LED Lightbox

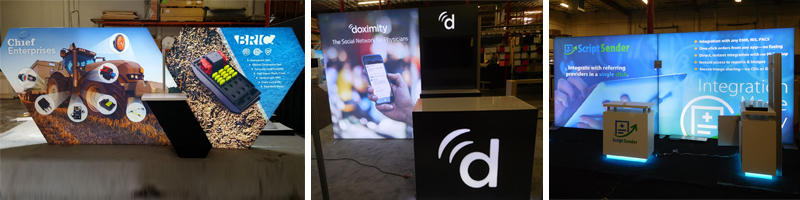

Stroll through any airport, mall, event, or trade show and you'll see hundreds of colorful LED lightboxes in every shape and size. Over the past few years, most have switched to Backlit Tension Fabric SEG Graphics. The reasons are obvious. Not only is fabric more durable than direct print graphics, but it’s also cheaper to ship and easier to maintain. And depending on the print process, the colors are vibrant and the details nearly photographic.

It's easy to assume that all LED lightboxes and manufacturers are similar, so the only real difference is price. Price matters of course, but there are other factors to consider.

8 Factors to Consider When Purchasing an LED Lightbox

1. Hardness and Durability

All LED Lightboxes start with an SEG aluminum frame. Every manufacturer engineers their frames using aluminum of varying hardness and durability. Less expensive lightboxes use softer aluminum because it’s cheaper. But cheaper aluminum scratches easily and tarnishes quickly. In addition, the wall thickness is often so thin that structural rigidity is compromised. For lightboxes mounted to a wall or assembled or disassembled at multiple trade shows, you will want aluminum with a 6063 specification. 6063 has better structural integrity and scratch resistant. If the supplier can’t answer that question, then you should be wary.

2. Availability

Does the manufacturer have the extrusion, LED lights, hardware, and accessories in stock? And are there extrusion options depending on the situation, such as one-sided vs two-sided, freestanding vs. wall mount. What if you need multiple quantities or quick ship options? Can individual parts be purchased if they are lost or damaged? You don’t want a manufacturer who dabbles in lightboxes.

3. Customization

3. Customization

Let’s say you need a width or height larger than the kits listed. Is it possible? If so, how complicated or expensive does it get? How about angles or shapes such as a hexagon? It’s easy to do squares and rectangles (for most manufacturers), but odd shapes and sizes are often a head-scratcher for those who only want to fulfill kits.

4. Print Quality

Asking the right questions is essential. 1. Dye-sublimation printing is the best. This ensures the colors are infused into fabric, not just printed on the surface. Many suppliers brag about “fabric printing” but it’s not always dye-sublimation, which requires two steps — printing to a paper material and then heat fusing the image to fabric. 2. Ask about the age of the printer. The dye-sublimation printer shouldn’t be more than two years old. Anything older than that means the print resolution is just OK, not photographic. 3. Just like clothing, the fabric quality can vary, which may not matter if the graphic is a throwaway and the resolution doesn’t matter.

5. Sewing and Sizing

Experienced manufacturers have this down to a science. They’ve done the calculations thousands of times with varying fabrics, and they know how to print, cut, and sew the fabric so it fits perfectly. Not too loose. Not too tight. Nothing is more frustrating than receiving a fabric graphic that doesn’t fit.

6. LED Lights

This could be a college course. Just understand the various color temperatures, lens, UL and ETL certification, module construction, etc. requires some research and patience. Like fabric, there are multiple ways to make LED lights cheaper, if cheaper is the only criteria. Skipping UL/ETL certification is shortcut. Using exposed connections or alligator clips is another. Sadly, it’s nearly impossible to know what you are getting before you get the LED lightbox. However, in this case, the old adage rarely fails, “If it’s too good to be true, then it probably isn’t.”

7. Accessories:

Most LED lightboxes are a one-trick pony. The are lightboxes. That’s it. But what if you want to add shelves, an iPad, a literature holder, wings or headers? What if you want to connect it to other lightboxes or create a full inline or island display. That requires and exhibit builder who has engineered the extrusion to be multi-functional, stocks lightbox accessories, and has the in-house talent to customize.

8. Assembly and Packaging:

It’s easy to assume that your display will ship in high-quality cases and packaging. Sadly, that’s rarely true. Most manufacturers use disposable one-way shipping materials. Your lightbox arrives undamaged. Now you have to ship it to the next show or to another location, but there’s nothing to protect it or keep it organized. Insist on reusable shipping materials, which precludes cardboard, shrink wrap, and thin foam. All three will be destroyed after one use. See examples. While you may have to pay a little more, it’s an investment that keeps giving show after show, assembly after assembly.

It’s important to remember that the pretty image you see on a website is just a rendering. What you receive is not. Ask the right questions and purchase your lightbox from a vendor you trust. Remember, your “may” be able to return the hardware, but the graphics, it’s yours whether you like it or not. Finally, keep in mind that you are buying a design, a marketing structure that represents your brand. It’s more than just an aluminum frame with graphics.

Contact Us

For more information about trade show or event marketing, give us a call or Contact Us. We welcome the opportunity to assist you with your next show.

Mel White, CEI